Gas Treating

Gas Treating

Sterling Auxiliaries Pvt ltd started manufacturing of Ethanolamines and Alkyl Alkanolamine plant from 2007. Sterling is the only Ethylene oxide facility in India to have continuous adjacent raw material supply. Sterling manufactures a wide range of Ethylene Oxide – based chemicals. Largest manufacture of MDEA and MDEA based specialty solvents in INDIA. One of the largest producers of Alkanolamines and MDEA based gas treating products with 30,000Mt capacity per annum.

Sterling’s manufacturing facility is in Dahej port of Gujarat State on western coast of India. We are logistically better placed since the bulk and Container port are just 2 km and 11 km respectively from the manufacturing facilities.

Sterling provides range of products to meets requirements for following applications.

- NATURAL GAS ( pipeline gas ) : H2S , CO2 , RSH removal to ppm / %v

- OIL REFINERIES : Mainly H2S removal

- SULPHUR PLANT TAIL GAS UNITS : H2S removal to < 10ppm(v)

- LNG / LPG PLANTS : H2S and CO2 removal to low ppm

- ACID GAS ENRICHMENT plants : High Selectivity

- FERTILIZER PLANTS : CO2 removal to low ppm

- STEEL PLANTS : CO2 removal to low ppm

- HYDROGEN PLANTS : CO2 removal to low ppm

- BIOGAS Unit : CO2, H2S removal

Products: (For MSDS or Technical Datasheet : gassweetening@sterlingaux.com)

Generic Amines :

Monoethanolamine (MEA)

Diethanolamine (DEA)

Methyl Diethanolamine (MDEA)

STERLING’s Formulated MDEA based specialty solvents:

MDEA is not efficient under all process conditions!

Additives used to enhance the performance of MDEA – Leading to a range of formulated amines……………

- MDEA + primary/secondary amines – ‘mixed’ amines

- MDEA + cyclic diamines – for CO2 removal

- MDEA + physical solvents – for mercaptan removal

- MDEA + pH adjusting components – low pressure treating

Advantages of Sterling’s Formulated MDEA based specialty solvents:

- stability – efficiency

- Increased acid gas processing ability.

- Significant energy savings through reduced reboiler duty.

- Decreased pumping requirements because of lower solvent circulation rates.

- Lower degradation – lower corrosion potential

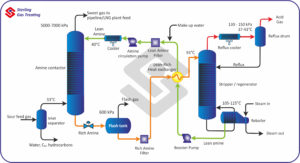

STERLING provides Technical services in 3 areas of Amine unit

-

- Simulation models – process engineering – supply of gas treating solvents is supported by

advanced simulation capabilities. STERLING uses PROTREAT Software for simulation and calculations - Amine analytical – chemistry – and how to control it

- Operations support – maintaining a high level of performance

- Address specific gas plant amine unit problems and assures optimal performance of the unit

- Simulation models – process engineering – supply of gas treating solvents is supported by

Download : Gas Treating Product Profile

More Enquiry : gassweetening@sterlingaux.com